Table of Contents

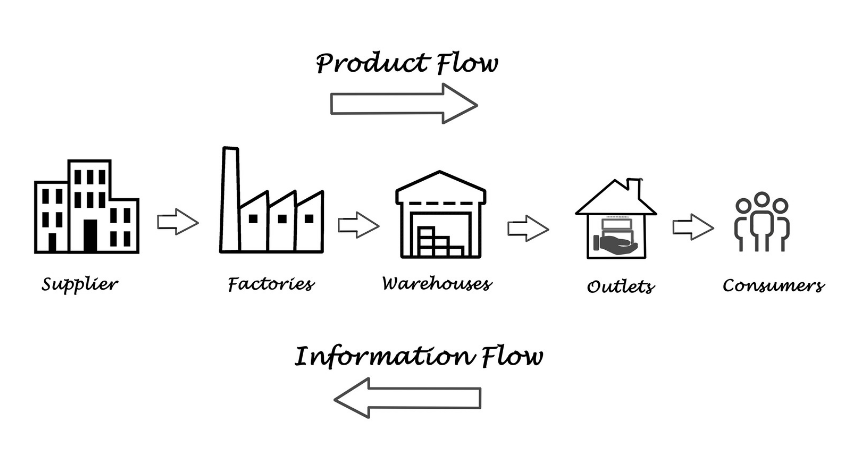

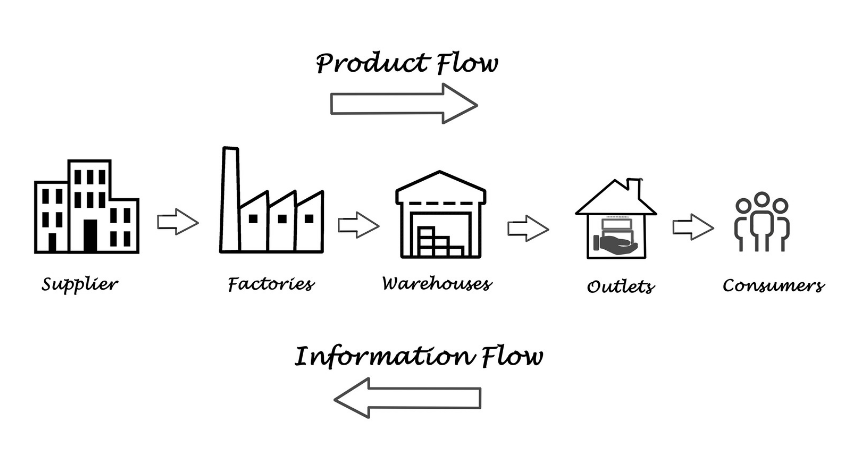

Given the many changes that are in place brought about by technology, it follows that even the most experienced of all supply chain managers have a lot to improve. Learning is a never-ending process. And it’s important so that your business’ supply chain efficiency can drastically improve. In today’s competitive business arena where so much more is demanded within the same timeframe of production, your business will suffer further in the competition if it doesn’t strive to become more efficient.

When it comes to building supply chain efficiency and meeting the all-time high customer expectations, it’s not always necessary to create big and drastic measures for an impactful change. What matters the most is you’re certain that all the tactics you apply are certainly those which are classified as the best business practices. What are those? Below is a list.

1. Track Your Supplies

The first step to improving your business’ supply chain efficiency is to have a well-defined system of tracking your supplies. This means you have enough supplies to meet production demand, at any given time. If not, production can be delayed, which in turn affects all the other next steps in the supply chain.

The first step to improving your business’ supply chain efficiency is to have a well-defined system of tracking your supplies. This means you have enough supplies to meet production demand, at any given time. If not, production can be delayed, which in turn affects all the other next steps in the supply chain.

As surprising as it may sound, there are still many businesses today that don’t use an automated inventory tracking system yet. This is especially true for small businesses and start-up businesses, where the inventory levels are still quite manageable, manually. If this is your business, take that fact as an opportunity for you now to grow and make changes.

There’s still so much room for a comprehensive and detailed tracking system, so you can have more information about the supplies you have in store. Good inventory management is also important to the long-term financial health of your business, so that’s all the more reason for you to ensure you’re able to have a smooth and efficient tracking of your supplies.

2. Increase Transparency In Your Supply Chain

It’s not surprising, for instance, that in the supply chain, there’ll be a lot of wasteful mistakes committed. These can be acceptable if they aren’t recurring. Once identified, these mistakes are immediately solved and corrected. It only becomes a problem when these loopholes aren’t solved, simply because they aren’t given attention to as there isn’t transparency.

You can improve supply chain management to a great extent by being able to reconcile the software numbers with the physical inventory count correctly. In effect, the likelihood of financial losses and lost inventory may also be reduced.

3. Assess Your Training Programs

This is where the need to regularly train your team comes in, even for those employees in the supply chain who have been with you for a long time. When you have new equipment and technology in place, it follows that you’ll also have to train your team for them to learn how to keep up with and operate that technology effectively.

When you do this, be sure to review all the training materials and match them with the procedures, to guarantee that topics also cover your current equipment. The goal of every recurring training session should always be to improve productivity, increase profits and stay up-to-date with the latest standards practiced in supply chain management.

4. Automate When Necessary

Not every single step in your supply chain has to be automated. But, if you find certain areas in your supply chain which you’ve identified as bottlenecks, that’s a telling sign you need to automate those areas. Technology isn’t replete with resources and advancements you can take advantage of, but not all of it will work well for your business. It’s up to you to match the automated technology with your business needs.

While it means changes and adjustments in your supply chain, it’s a change worth going through. You can now make use of automation to create positive changes in your supply chain along the lines of improving efficiency, increasing production, and streamlining certain tasks and processes in your supply chain.

Conclusion

By applying the business practices above in your own supply chain, you too can make your business soar to higher levels of success. Knowing how to improve your supply chain is a crucial step to ensuring the efficacy of each operation, in every step. That way, you can keep everything running smoothly and make it competitive in this world of fast-paced industries. The strategies above can lead to maximum profitability, increased production speed, and higher customer satisfaction, in general.