Table of Contents

How 3D Printing Technology Is Used in the Space Industry?

With the development of 3D printing, additive manufacturing is gradually making its way into a variety of industries, and the space sector does not lag behind this promising trend.

Today, 3D printing has the potential to give the spacecraft a new face and facilitate a variety of missions. The future applications of 3D printing in the space industry are practically limitless and not yet fully explored, so let’s, for now, focus on things we already know additive manufacturing and space 3D printing.

What is 3D printing or additive manufacturing?

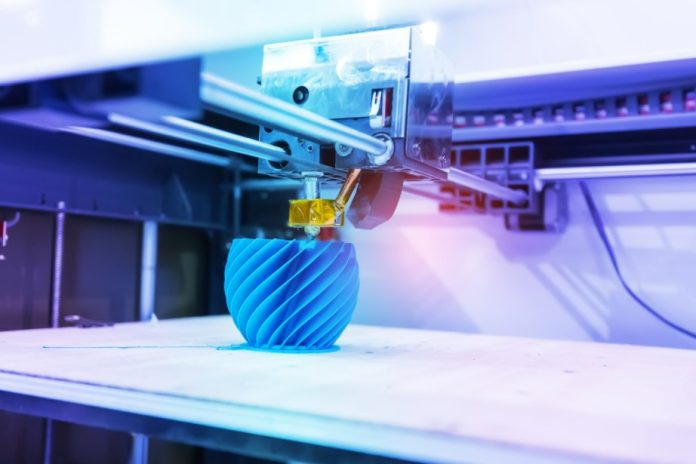

3D printing, also known as additive manufacturing, is a technique for building a three-dimensional object layer by layer from a computer-generated model. The space industry can benefit from this technology because it has the potential to redefine manufacturing and open up previously impossible opportunities. Most importantly, additive manufacturing can mass-produce spaceship components parts quickly and affordably.

3D printing, also known as additive manufacturing, is a technique for building a three-dimensional object layer by layer from a computer-generated model. The space industry can benefit from this technology because it has the potential to redefine manufacturing and open up previously impossible opportunities. Most importantly, additive manufacturing can mass-produce spaceship components parts quickly and affordably.

What are the benefits of 3D printing in the space industry?

Even though the full potential of 3d printing in the space industry has not been uncovered yet, it already features a lot of benefits. The most prominent ones include:

1. Cost-Effective Manufacturing

Traditional manufacturing processes need a lot of raw resources, whereas 3D printing uses a lot less of them. Lasers are employed in this technique, and lasers ensure accuracy. As a result, there are no residual resources to reuse, while manufacturing becomes more efficient and highly optimized.

To continue, raw materials are inexpensive to manufacture and use, allowing them to be launched into space at a lower cost and save money. This means they may be used in unexplored ways.

2. Remote Production

What’s even more intriguing about 3D printing is the way it operates even from your home office, which means it can be controlled from anywhere on the planet. This offers it a big advantage since it is no longer limited by the region in which the user is.

It’s predicted that 3D printing would be very beneficial for populating Mars or the Moon, since people will be able to manufacture anything right there, from rocket components and food to 3d printed spacecraft.

On the International Space Station, for example, NASA 3D printed a really intriguing exhibit of a rocket wrench, and more 3d printed rocket parts will surely follow.

3. Weight Reduction

When in space, kilograms matter a lot since too much weight may turn any mission into a disaster if the rocket encounters resistance and doesn’t manage it anymore. 3D printing, on the other hand, is quite advantageous in this case since it reduces weight, which leaves less space for mistakes.

In other words, 3D printing is a highly beneficial tool and also become an essential tool in the space sector because it saves weight.

4. Design Freedom

Engineers may leverage the use of 3D printing capabilities to change designs by putting lattice structures to use. The most difficult engineering challenges are usually solved using this technique that produces simple yet highly effective outcomes.

3D printing may also be used to create rocket components with the design freedom that the space industry requires in mind. Technology is increasing the design area, allowing for the creation of part forms that many would have never even imagined. When it comes to casting or machining, these forms are out of the ordinary.

5. Sustainability

Waste is minimized by 70% to 90% when using 3D printing technology, compared to any of the other conventional approaches that came before made in space 3d printers.

3D printing promotes the repurposing of industrial resources, such as recycling plastic to create new materials. This is good news for those people who seek a greener planet. When considering how this technology will function in the long term, it is clear that it will have the most promising future as far as the space sector goes. One day, we may even see a 3d printed rocket.

What Space Companies are Using 3D Manufacturing?

More than one 3d printed rocket company makes full use of the new technology. Fleet Space, Skyrora, Relativity Space, and Rocket Lab are important names in the space industry. They all have embraced 3D printing and are using it to create advanced technology.

Final Thoughts

3D printing is a cutting-edge technology that has the potential to improve space travel. It’s both sustainable and very efficient, so there’s no wonder that more and more space businesses are using it to develop their equipment. And the even better news is that nowadays any company can access a space 3d printer.